1. Motivations for sustainable textiles

Sustainable textiles (also known as eco-fashion or eco-textiles) related to designing, producing, marketing, and selling apparel in the most renewable way possible, which embodies the improvement of resource efficiency, expansion of the product’s life span, recycling, phasing out microfiber release, upholding human rights, and environmental protection.

Currently, the textiles and apparel industry is highly unsustainable. It is among the most polluting industries in the world. Since fabrics are used in cheap garments, they are produced from synthetic materials that could survive more than 1,000 years in a landfill and contribute 35% to microplastics in the ocean. Most clothing contains at least one type of biodegradable plastic. According to the World Bank, the industry uses 93 billion cubic meters of water annually, which is equivalent to the consumption needs of five million people, while 87% of the total materials input to produce clothing are disposed into the landfill. Moreover, according to Quantis, the textiles industry produces 1.2 billion tons of greenhouse gas emissions every year. It contributes 17-20% to global water pollution and generates about 21 billion tons of garbage annually. It is expected that by 2050, the industry will utilize 25% of the world’s carbon budget.

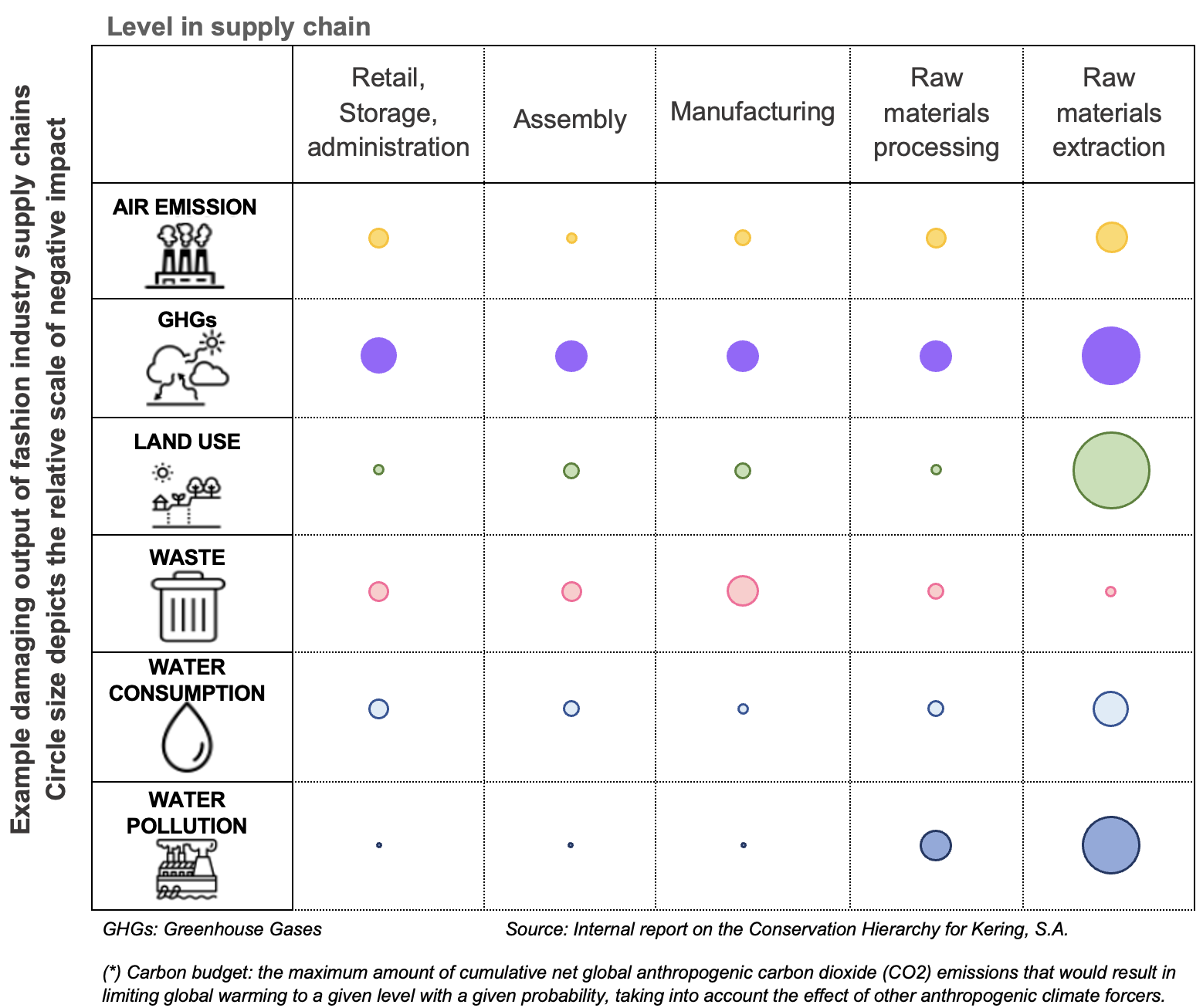

The table above, adapted from Bull et al. (2019) Internal report on the Conservation Hierarchy for Kering, S.A., indicates that raw material extraction is the highest risk level on the supply chain for biodiversity impacts because production drives land-use change, which is the greatest direct threat to biodiversity globally. Processing, manufacturing, retailing, and administration also pose indirect risks to biodiversity.

To alleviate the devastating impact of textiles and apparel industry on the environment, sustainable textiles are increasingly noticeable. Moreover, there are many drivers for the transition to the green industry worldwide.

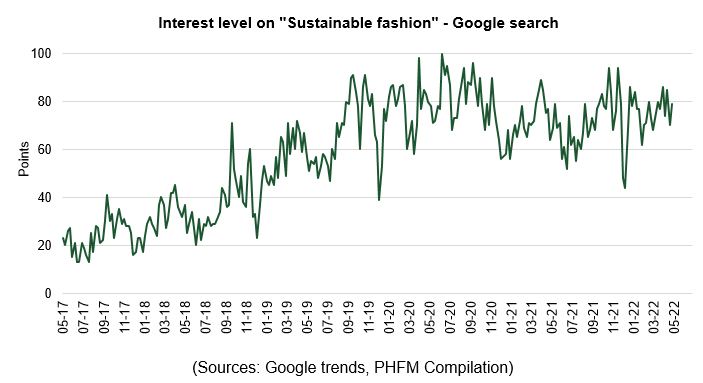

(1) Enhanced awareness is one of the key drivers for green transformation. According to Forbes, 88% of consumers want brands to help them become more environmentally friendly. According to the survey conducted by Vogue, more than 65% of consumers would pay a premium for eco-friendly products. Additionally, the level of interest for google search “sustainable fashion” soared from 2017 to 2019, then maintained a steady high level in 2022. This makes being a sustainable supplier be a selling point. Hence, it would be more favorable for fashion brands to build their reputation, expand market share, and enhance competitive advantages if they have the “green” brand awareness.

(2) The organic clothing system would also ease social problems associated with traditional textiles. It ensures fair wages and trade, promotes safe working condition, and pushes sweatshop-free and cruelty-free.

(3) Eco-fashion is reinforced by many Governments worldwide. The European Commission recently adopted its Strategy for Sustainable and Circular Textiles, which aims that by 2030 (1) all products on the EU market should be recyclable, durable, free of hazardous substances, and made from recycled fibers; (2) Turning away from fast fashion; (3) Re-use and repair services would be widely accessible; (4) Circular clothes become the norm as producers in the value chain have adequate capabilities for recycling and minimal incineration and landfilling.

2. Market for sustainable fashion

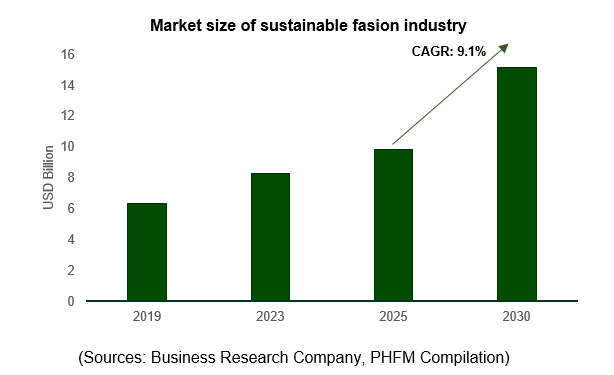

According to Business Research Company, the global ethical fashion industry is worth over USD 6.35 billion in 2019, with a CAGR (2015-2019) of 8.7%. It is expected to hit USD 8.25 billion in 2023. Furthermore, according to sustainable fashion industry statistics, the industry is expected to grow to USD 9.81 billion in 2025 and USD 15.17 billion in 2030 at a CAGR of 9.1%.

The market is divided into types based on fair trade, animal cruelty-free, eco-friendly, and charitable brands. Recently, the animal cruelty-free segment contributed the largest proportion to the industry – 40%. The eco-friendly products segment is expected to develop the fastest in the future, with a compound annual growth rate of 11.6%.

In 2018, the fashion industry joined the UN Climate Action initiative by launching the Fashion Industry Charter for Climate Action (“UNFCCC”). By 2021, 132 brands were joining the charter. Global major brands have taken action to respond to the rising trend of the ethical fashion:

H&M: H&M aims to raise the input proportion of source materials from 17.9% of recycled polyester to 30% in the total materials, 63.7% of recycled polyester to 100% from the overall polyester percentage, and 50.7% chrome-free, animal-based leather to 100% from the overall leather percentage started from 2021 to 2025.

H&M: H&M aims to raise the input proportion of source materials from 17.9% of recycled polyester to 30% in the total materials, 63.7% of recycled polyester to 100% from the overall polyester percentage, and 50.7% chrome-free, animal-based leather to 100% from the overall leather percentage started from 2021 to 2025.

Nike: Nike aims that 100% of waste diverted from landfills of the company supply chain with at least 80% recycled back into Nike products and other goods; 10x the amount of finished products waste refurbished, recycled, or donated; 0.5 million tons of GHGs emissions reduced through increasing the use of environmentally preferred materials to 50% of all key materials.

Nike: Nike aims that 100% of waste diverted from landfills of the company supply chain with at least 80% recycled back into Nike products and other goods; 10x the amount of finished products waste refurbished, recycled, or donated; 0.5 million tons of GHGs emissions reduced through increasing the use of environmentally preferred materials to 50% of all key materials.

Adidas: Adidas targets across its supply chain (1) 40% water intensity reduction at Tier 2 supplier facilities; (2) adoption of renewable energy at strategic Tier 1 and Tier 2 supplier facilities to keep emissions flat; (3) 80% of supplier facilities to achieve the highest level of compliance (level 3) with ZDHC ‘Manufacturing Restricted Substances List’ for 80% of the chemicals used for production.

Adidas: Adidas targets across its supply chain (1) 40% water intensity reduction at Tier 2 supplier facilities; (2) adoption of renewable energy at strategic Tier 1 and Tier 2 supplier facilities to keep emissions flat; (3) 80% of supplier facilities to achieve the highest level of compliance (level 3) with ZDHC ‘Manufacturing Restricted Substances List’ for 80% of the chemicals used for production.

The Children’s Place: The Children’s Place set the target (1) to source 100% of recycled material for the polyester fibers used in pocket bags used in our denim and woven bottoms, woven labels, and zipper tape by the end of 2025, (2) to reduce absolute scope 1 and scope 2 market based GHG emissions across global operations by 30% by the end of 2030.

The Children’s Place: The Children’s Place set the target (1) to source 100% of recycled material for the polyester fibers used in pocket bags used in our denim and woven bottoms, woven labels, and zipper tape by the end of 2025, (2) to reduce absolute scope 1 and scope 2 market based GHG emissions across global operations by 30% by the end of 2030.

![]() Decathlon: Decathlon commits that 100% of products would follow the eco-design by 2026, which satisfies two requirements: reducing the environmental impact by at least 10% and 70% of product weight made from recycled polyester.

Decathlon: Decathlon commits that 100% of products would follow the eco-design by 2026, which satisfies two requirements: reducing the environmental impact by at least 10% and 70% of product weight made from recycled polyester.

Eddie Bauer: Eddie Bauer attempts to achieve 50% of fabrics used in production having BLUESIGN® approval, 50% of polyester and nylon made from recycled content, and 100% of down and feather be complied with the Responsible Down Standard by 2025.

GAP: GAP pursues the goals of 50% recycled polyester by 2025, 100% recycled polyester by 2030, 100% of cotton converted to organic or recycled cotton by 2030, 80% of sourcing allocated to green-rated suppliers, and work toward zero discharge of hazardous chemicals.

GAP: GAP pursues the goals of 50% recycled polyester by 2025, 100% recycled polyester by 2030, 100% of cotton converted to organic or recycled cotton by 2030, 80% of sourcing allocated to green-rated suppliers, and work toward zero discharge of hazardous chemicals.

UNIQLO: Fast Retailing signed Fashion Industry Charter for Climate Action in JAN 2020, supporting the goal of the Paris Agreement to reduce the emission of GHG by 30% by 2030.

UNIQLO: Fast Retailing signed Fashion Industry Charter for Climate Action in JAN 2020, supporting the goal of the Paris Agreement to reduce the emission of GHG by 30% by 2030.

Columbia Sportswear: The Company aims to reduce manufacturing carbon footprint by 30% in 2030 and conducts a robust improvement plan.

New Balance: New Balance sets the target to source 100% preferred leather and 50% recycled polyester, use 100% renewable electricity for operations, eliminate the use and discharge of hazardous chemicals, achieve zero waste in landfill by 2025, and achieve a 30% reduction in CO2 emissions by 2030.

New Balance: New Balance sets the target to source 100% preferred leather and 50% recycled polyester, use 100% renewable electricity for operations, eliminate the use and discharge of hazardous chemicals, achieve zero waste in landfill by 2025, and achieve a 30% reduction in CO2 emissions by 2030.

The following global certification schemes boost good standards that diminish environmental impacts of operation and manufacturing processes globally.

Sustainable production of raw materials:

Manufacturing processes:

Eco-tags on fashion products:

3. Greening the textiles industry in Vietnam

The Vietnam Textile and Apparel Association (VITAS) has set a goal of “going green” with a plan that:

a. By 2023, the industry would reduce energy consumption by 15% and water consumption by 20%. By 2030, the industry would become more sustainable with 30 international brands.

b. Increase the proportion of used recycled polyester fiber to 20% and organic cotton to 15%.

c. Raise the number of manufacturers achieving and maintaining the HIGG Index, ZDHC, ISO 14001, and other certifications.

d. Diminish waste via cleaner production method, BATs, and BEPs.

e. 10% of electricity is derived from renewable sources.

f. Continuously reduce hazardous chemicals.

Acts of strong domestic players in working towards the eco-textiles industry are as follows:

a. Century Synthetic Fiber Corporation (HSX: STK)

By 2021, STK has indirectly recycled 3.04 billion waste plastic bottles into recycled fibers, contributing to reducing plastic bottle waste in the ocean. In addition, STK has developed colored yarns using dope-dyed technology, creating an alternative to the traditional dyeing process, helping customers lower clean water consumption by 89%, and diminishing the discharge of wastewater and chemicals into the environment, contributing to achieving the commitments of the ZDHC. Recently, the Company also recycles waste fibers into input PET chips, decreasing environmental emissions. Moreover, STK implements a solar energy project, which curbs a 10% annual carbon footprint and declines 530 thousand tons of CO2 during the project’s operation.

STK has integrated Sustainable Development Goals (SDGs) into its daily operations. The Company sets the following goals for sustainable development during the period 2022-2023:

(1) Strictly comply with production standards of REACH 168, OEKO-TEX 100, GRS, and standards of brands to protect customers’ health consumer goods.

(2) Developing more new colors of dope-dyed yarn, which are environmental-friendly.

(3) Raising the proportion of recycled yarn to 54.3% of the Company’s total revenue in 2022.

During the period from 2022 to 2025, STK also set the following targets:

(1) Reducing carbon footprint by squeezing electrical energy consumption at the factories.

(2) Applying AI systems in production, deploying POC software – production control center in POY and DTY factories, helps to increase production efficiency and reduce waste.

(3) Application of automation technology in packaging.

(4) Raising the proportion of recycled yarn to 100% of the Company’s total revenue in 2025.

b. Thanh Cong Textile Garment Investment Trading Joint Stock Company (HSX: TCM)

TCM has employed a strong environmental, social-oriented manufacturing process, which makes it stand out as a long-rooted and prestigious player in the industry. Currently, TCM implements and maintains the Environmental management system following the ISO14001-2015 certification by the BSI organization. The company would gradually raise the HIGG Index score every year. In addition, the products of TCM are constantly improving in quality, meeting customer requirements, and complying with OEKO-TEX 100 standards. Furthermore, TCM conducts product quality management according to SQP (Supplier Qualification Program), a standard that measures compliance and promotes business improvement. Moreover, the company is certified with WRAP – a globally recognized Responsible Manufacturing Certificate which ensures consumers that the company’s products are manufactured ethically and by fairly treated workers. TCM aims to maintain these certifications in the future.

c. TNG Investment and Trading JSC (HNX: TNG)

TNG also ensures its manufacturing process is as “green” as possible. Like peers, TNG follows and applies GRI for ESG standards. Furthermore, the company qualified for domestic standards on ESG, such as the Certificate of registration of environmental protection plan issued by the People’s Committee of Thai Nguyen.

TNG has successfully replaced plastic bags with paper bags made from recycled paper, artificial down like cotton to replace fleece. Besides, it commits not to use chemicals and materials on the banned list that contain toxic elements above permitted environmental standards according to company procedure no. QTQLCT/QTQLKL&ATSP.07. In 2020, the company saved 45% of power consumption on the identical product compared to 2019. Moreover, TNG builds a green factory, Vo Nhai, to reduce the GHGs.

d. Song Hong Garment Joint Stock Company (HSX: MSH)

To minimize adverse environmental impacts, MSH focuses on building and monitoring the production process with strict standards across the operations process, from negotiating with customers and planning input materials, to researching and documenting the technical design for product to minimize the failure rate in production and avoid waste. To gradually take initiatives in the supply of raw materials, the company has invested in and operated a cotton factory with the top modern production line in Vietnam, using all primary raw materials with no impurities or chemicals.

4. Conclusion:

The processing of “greening” the domestic textiles industry is accelerating. Companies who run ahead in this race would be credit suppliers to obtain orders from global brands, enhance competitive advantages, engage more deeply into the world supply chain, and benefit more from FTAs.